Versatile and cost-effective

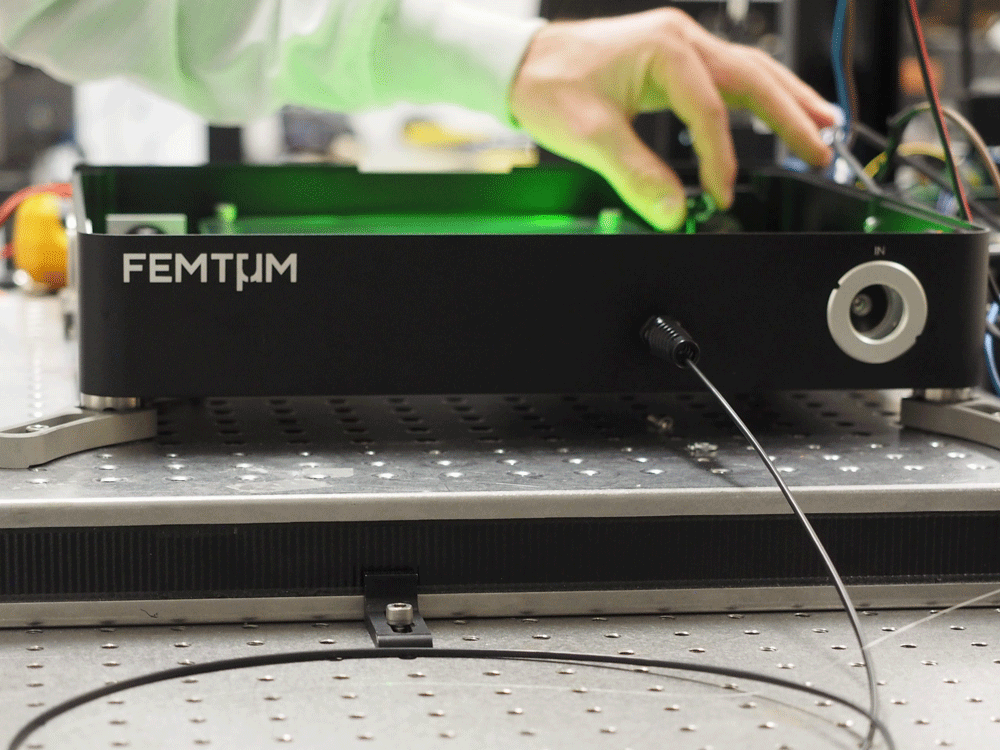

The 50W femtosecond laser FemtoLux is a versatile and cost-effective tool with high performance that has been specially developed for the requirements of micro material processing.

On the one hand, the laser system offers ultra-short pulses (USP) down to the femtosecond range, with high pulse energy and beam quality. These are particularly important in the high-precision processing of brittle materials such as glass, ceramics and metal, where the heat introduced by longer laser pulses (such as nanosecond pulses) leads to craters, microcracks and chipping. In addition, processing with the FemtoLux’s USP radiation achieves an extremely high surface quality.

Secondly, the laser system is equipped with the most flexible burst technology available on the market. Research in recent years has shown that the ablation rate for many materials can be significantly increased without negatively affecting the process quality if the laser pulses are divided into bursts (pulse packets) instead of the single pulse mode. This is particularly important for industrial 24/7 applications. The ablation speed and process quality can be greatly influenced by varying the energy distribution, i.e. by specifically setting the burst setting. This allows industrial processes such as drilling, cutting or surface structuring to be optimized and individually adapted.

Unique technologies

A unique feature of the FemtoLux burst modes is the integrated Active Fiber Loop technology, which enables up to 1100 pulses in the GHz burst and up to 10 pulses in the MHz burst, as well as combined MHz and GHz bursts. The pulse shape of the GHz bursts is also adjustable.

The FemtoLux delivers up to 300 µJ in single shot mode with adjustable pulse repetition rate from single shot up to the MHz range. This with adjustable pulse duration from <350 fs to 1 ps. In burst mode, even up to >750µJ total pulse energy is available. Alternatively, a high-energy version with 1mJ at 10kHz repetition rate and fixed pulse duration is also available. The laser has pulse-on-demand with jitter <20 ns. This enables a consistent and equidistant pulse spacing in micro material processing as well as adjustable repetition rates for the realization of complex geometries. The laser beam offers an M2 < 1.2. To enable the laser beam to be used for a wide range of different materials, the laser system can be equipped with second (515 nm) and third (343 nm) harmonics.

The laser system is also equipped with a Direct Refrigerant Cooling System (CRE), an innovative cooling system based on a compression refrigeration machine that reduces power consumption by almost 50% compared to conventional water coolers and eliminates work and maintenance costs for the cooling system.