FemtoLux

High-power femtosecond lasers for science and industry

The FemtoLux laser has been designed from the ground up for maximum reliability, seamless integration and continuous 24/7/365 operation without maintenance. A wide range of options allows it to be customized to your desired material processing tasks.

Features

- At 1030nm

50W typical average power and > 300 µJ maximum pulse energy - Optional second and third harmonics with

515nm: 20 W average power and > 50 µJ maximum pulse energy

343nm: 10 W average power and > 25 µJ maximum pulse energy - High-energy version available with 1 mJ pulse energy at 10 kHz

- > 750 µJ Total energy of a MHz burst pulse train

- < 350 fs – 1 ps, optional extension up to 1 ns

- Single shot up to 4 MHz

- MHz, GHz, MHz+GHz burst modes

- Pulse-on-demand (PoD), with low jitter of 20 ns (peak-to-peak)

- < 0.5% RMS power stability over 100 hours

- M² < 1.2

- Beam circularity > 0.85

- Power supply unit and cooling installed in a 19″ housing with 4 height units

- Turn-Key System

- Compatible with galvo and polygon scanners, as well as PSO controllers

Special features

- Maintenance-free for best 24/7 use

- “Dry c/ooling” (no water circulation)

- Most flexible MHz-GHz mode

- small foot print

Applications

- Cutting, removing, structuring

- Through Glass Vias (TGVs) production in glass

- Thin-film glass cutting

- Nitinol stent processing

- Production of micro-electronics

- Heat-sensitive cutting of polymer

- Labeling thick glass

- Black and color marking of medical tools

What users like about the FemtoLux

We, SuperbIN company, are provider of customized laser machine systems. One of main requirements (besides specifications) from our customers are reliability and maintenance free operations. We have been using FemtoLux 30 from Ekspla for 4 months under intense conditions. FemtoLux 30 from Ekspla delivers stable parameters, maintenance free operation and establishes itself as reliable laser source for micromachining applications.

In general, we like the extended capabilities of the laser output with respect to higher power and rep rate. We were able to make good cuts very quickly. The higher rep rates help us with edge quality. We have been able to cut thicker materials than with our other laser sources. We really like the fact that it is easier to work with. The compact chiller and the rack mount controller are great features and save us a lot of space. The technical support has been very responsive and complete. We have already ordered a second laser.

The FemtoLux30 has been very easy to use with the PI stages (XY and Rotation axes for the samples plus the typical Z axis for the focusing lens) in our micromachining system. As someone who worked with Ti:sapphire lasers (much shorter pulses) in the past, I am very pleased with how robust the FemtoLux system is.

FemtoLux 30 femtosecond laser system has been valuable in our laboratory, demonstrating its capability in various material micromachining tasks. It stands out for its low maintenance requirements, and with the availability of harmonics and burst mode, it efficiently processes different materials with high quality.

Applications

Glass processing

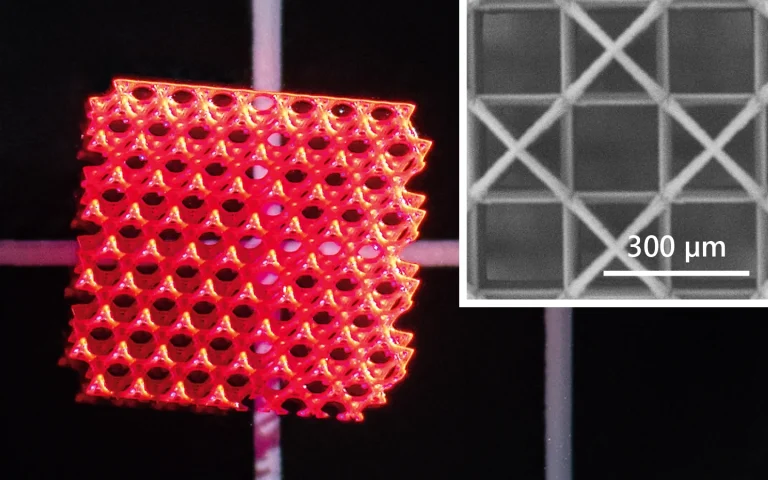

Femtosecond lasers have taken the possibilities for glass processing to a new level. As a result, it is now possible to ablate complex structures down to the µm range quickly and precisely.

Metalworking

In metal processing, femtosecond lasers are the ideal solution for producing complex, fine structures at high process speeds. They also enable black/white and color markings without the use of chemical additives.

Polymer processing

Femtosecond lasers are particularly suitable for processing polymers due to their particularly short pulse duration. As the short pulse duration results in very little heat input into the material, ablation is very precise and does not change the material properties.

Editing other materials

Compared to traditional processing methods, femtosecond lasers allow exceptional precision during processing due to the particularly short pulse duration. They can therefore be used to efficiently create sophisticated and unconventional shapes and surfaces.

Applications

Scientific publications

Comparative analysis of microlens array formation in fused silica glass by laser: Femtosecond versus picosecond pulses

L. Zubauskas, E. Markauskas, A. Vyšniauskas, V. Stankevič, and P. Gečys, Journal of Science: Advanced Materials and Devices 9 (4), 100804 (2024). DOI: 10.1016/j.jsamd.2024.100804.

The growing demand for flexible, high-quality fabrication of free-form micro-optics drives the development of laser-based fabrication techniques for both the shape formation and surface polishing of optical elements. In this paper, we performed a thorough and systematic study on fused silica glass ablation using 10 ps and 320 fs duration pulses. Ablation processes for both pulse durations were optimized based on the measurements of the removed material layer thickness and surface roughness, and by analyzing the topographies of ablated cavities to remove material layers as thin as possible with minimum surface damage. Our findings demonstrate higher process resolution and surface quality for femtosecond pulses. Ablation of pre-roughened glass reduced the minimal removable glass layer thickness well below the 1 μm mark for both pulse durations, improving the process resolution. The minimal removable glass layer thickness was 14 times smaller for the femtosecond pulses, with up to 4.5 times lower surface roughness compared to samples processed with picosecond pulses. On the other hand, results revealed faster glass removal rates with picosecond pulses. In the end, arrays of microlenses were fabricated with both pulse durations and subsequently polished with a CO2 laser. Results revealed higher performance of microlenses fabricated with femtosecond pulses, providing better focusing capabilities and lesser beam scattering. Finally, this study demonstrated the successful fabrication of free-form optical elements with femtosecond and picosecond pulses, demonstrating the versatility and the potential of laser-based techniques.

The ultrafast burst laser ablation of metals: Speed and quality come together

A. Žemaitis, U. Gudauskytė, S. Steponavičiūtė, P. Gečys, and M. Gedvilas, Optics & Laser Technology 180, 111458 (2024). DOI: 10.1016/j.optlastec.2024.111458.

Utilization of high-power ultrafast laser for ablation-based industrial processes such as milling, drilling or cutting requires high production rates and superior quality. In this paper, we demonstrate highly efficient, rapid and high-quality laser micro-machining of three industrial metals (aluminum, copper, and stainless steel). Our proposed optimization methods of pulse energy division in time result in simultaneous enhancement of ablation efficiency (volume per energy) and ablation rate (volume per time) while maintaining a focused laser beam on the target surface and high resolution. A high-tech femtosecond burst laser, producing laser pulses of τ = 350 fs duration and intra-burst repetition rates of fP = 50 MHz, was employed in the experiments. Due to the utilisation of bursts, material removal efficiency and removal rate were increased by 18.0 %, 44.5 %, and 37.0 % for aluminium, copper, and stainless steel if compared with the best performance of single-pulses. In addition to the high processing rate, processing by burst mode resulted in lower surface roughness. This technique is believed to be a solution enabling extremely high femtosecond laser powers for precise microfabrication.

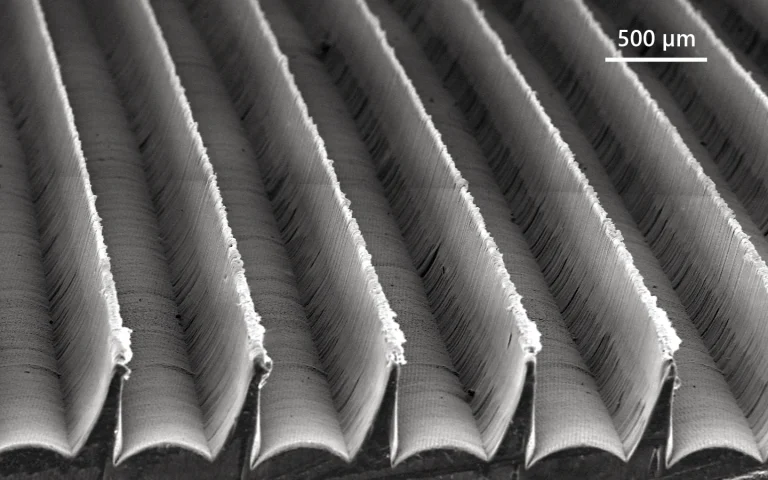

Ultrashort Pulse Bursts for Surface Laser Polishing

S. Steponavičiūtė, P. Gečys, G. Račiukaitis, M. Gedvilas, and A. Žemaitis, in Optics, Photonics and Lasers OPAL’ 2024 Conference Proceedings, S. Y. Yurish, ed. (IFSA Publishing, 2024), pp. 44.

Laser polishing offers numerous advantages, one of which is the convenience of using the same system for the

whole manufacturing process. In this work, an ultrashort pulse laser operating in a GHz burst regime was used to polish

stainless steel. The aim was to minimize surface roughness, characterized by the average roughness parameterRa. Different

laser processing parameters (average laser power, number of pulses per burst, scanning speed, hatch size) were varied to polish

samples that were covered in laser-induced periodic surface structures (LIPSS). Thermal effects, such as melt layer formation,

were noticed and discussed. It was demonstrated that LIPSS can be erased and the initial surface roughness of 73 nm was

reduced to 41 nm using 100 pulses per burst and burst fluence ofFB = 0.15 J/cm2.